IASS 2024 Workshops

Photo by: NCCR Digital Fabrication

Pre-symposium workshops will be held in person, on Sunday August 25th 2024, and will all be held at the Institute of Technology in Architecture (ITA), on the ETH Zurich Hönggerberg campus.

Registration for workshops will open on 1 June. You can book the workshops via our registration page. All “Early Bird” registrants will be notified when the workshops are open and available for registration.

See the 6 workshops on offer this year:

1

“Ameba – The Opt Art.”

Time: 08:30 to 12:30 & 13:30 to 17:30 (full-day) | Audience: students, researchers, architects, engineers, designers | Participant numbers: min 10, max 25 | Requirements: laptop, installed software: Rhinoceros 3D, Grasshopper, Ameba (Ameba free accounts will be supplied) | Prerequisites: none | Participation Fee: CHF 30- (coffee/tea & light lunch included)

About the Workshop

Since the advent of computer-aided design technology in the late 20th century, the exploration of form finding based on structural performance has gained momentum in architecture, design, and art. This evolution is closely intertwined with the development of structural morphology, ranging from the barrel arches and domes of ancient Greece and Rome to the pendentives and flying buttresses of the Byzantine and Gothic periods. Architectural design has progressed from the physical models employed by visionaries such as Antonio Gaudi and Frey Otto to the adoption of the topological optimisation method proposed by Mike Xie, reinforcing the intrinsic relationship between architectural morphology and structural optimisation.

This workshop introduces a novel approach to generative architectural design, aiming to redefine the art of structural design in alignment with the symposium theme. Participants will gain insight into the foundational principles of topology optimisation and its applications in design and architecture through lectures delivered by Nic Bao and Mike Xie. Additionally, participants will acquire basic skills in using topological optimisation and the related software Ameba. Emphasising structural performance-based design, the workshop seeks to bridge the gap between architectural design and structural optimisation. Its ultimate goal is to empower participants to explore new frontiers in generative design and challenge the boundaries of traditional approaches.

Tutors

Dr. Ding Wen ‘Nic’ Bao is a Senior Lecturer in Architecture, Architecture Technology Stream Coordinator and Director of FormX Research Lab at School of Architecture and Urban Design, RMIT University; Director of B.W Architects (BWA) and Wonderform Studio; Partner of Ameba Institute of Engineering Structure Optimization; Registered Architect in Australia, UK, and US.

Prof. Yi Min ‘Mike’ Xie is a Distinguished Professor at RMIT University, Director of RMIT Center for Innovative Structures and Materials (CISM); Australian Research Council Laureate Fellow; Fellow of Australian Academy of Technology and Engineering; Founding Director of Ameba Institute of Engineering Structure Optimization.

2

“Form-finding by the Force Density Method.”

Time: 08:30 to 12:30 & 13:30 to 17:30 (full-day) | Audience: students, researchers, teachers, practicing professionals | Participant numbers: min 10, max 30 | Requirements: laptop, with Windows and Microsoft Excel installed (additional resources, such as VBA/MS Excel based software Stiff3D, example data sets, videos etc., will made available in time) | Prerequisites: some knowledge about structural mechanics and the interaction of form and force, interests in numerical methods | Participation Fee: CHF 30- (coffee/tea & light lunch included)

About the Workshop

The topic of this workshop is: form finding by the force density method – 50 years of history and the latest state. The workshop is principally focused on the mechanical and mathematical basics of numerical form finding of minimal nets and surfaces and the specific approach by the force density method. Historical developments covered:

- the inventors Klaus Linkwitz and Hans-Jörg Schek and the 1972 Munich Olympic Roof as the occasion of invention

- the original and the extended theory including the consistent imbedding into nonlinear continuum mechanics and membranes

- “classical” applications like cable nets

- “generalised” applications like grid shells, hybrid structures (mixing positive and negative force densities)

- “new” applications like tensegrities, dual graphs and optimised strut-and-tie-models

- methodological subjects like length constraints, nonlinear optimization techniques, or stabilisation of kinematic modes

The workshop is relevant in terms of the importance of numerical form-finding for modern lightweight construction and the holistic background knowledge required for this.

The workshop will comprise an introductory lecture, studying the topic by hands-on-examples and basic implementations, own principal exercises with the available software, introduction to non-linear form finding and additional constraints, modelling, and solution of challenging (small) problems in guided group work.

Tutor

Prof. Dr. Kai-Uwe Bletzinger is Professor of Statics at the Technical University Münich (TUM). He conducts research in the field of computational mechanics for static-dynamic calculation, simulation and optimisation and their integration into the digital design chain. He develops methods for the numerical recording of the interactions of components and structures with the design (CAD-FEM coupling with the isogeometric method, IGA), the load (fluid-structure interaction, FSI, numerical wind tunnel, computational wind engineering, CWE) and the structural geometry. Prof. Bletzinger and his working group are international leaders in the field of shape finding and shape optimisation.

3

“Machine Learning-Assisted Computational Structural Design.”

Time: 08:30 to 12:30 & 13:30 to 17:30 (full-day) | Audience: students, researchers, practicing professionals | Participant numbers: min 10, max 15 | Requirements: laptop, with Rhino installed | Prerequisites: none | Participation Fee: CHF 30- (coffee/tea & light lunch included)

About the Workshop

In this three-part workshop, participants will explore the intersection of computational design and machine learning (ML) algorithms to generate equilibrated structures.

Part One of the workshop will provide an overview of computational design using ML, laying the foundation for the subsequent tutorial and design exercise.

Part Two of the workshop will focus on a step-by-step tutorial on implementing a design workflow using Combinatorial Equilibrium Modelling (CEM), a computational form-finding method based on graphics statics and graph theory, and various ML applications, using Large Language Models (LLMs), and Generative AI.

In Part Three, participants will learn how to use CEM and various ML algorithms in a design exercise. Informed by the ML tool’s suggestions, they will explore the design space of structures to generate non-conventional 3D spatial networks in equilibrium. By the end of the workshop, participants will have gained hands-on experience in a novel ML-supported structural design method with the ability to implement this innovative approach to structural design in their own work.

Tutors

Kam-Ming Mark is Assistant Professor of Architectural Structures at the University of Hong Kong.

Lazlo Bleker is a PhD student and research assistant at the Professorship of Structural Design at the Technical University of Munich.

Pierluigi D’Acunto is Assistant Professor at the Professorship of Structural Design at the Technical University of Munich.

Karla Saldaña Ochoa is Assistant Professor in the School of Architecture at the University of Florida.

Dr. Guo Zifeng is a Computational Design Developer at STRABAG, Germany.

Kaleb Smith is an AI and Deep Learning Expert at NVIDIA AI Technology Center.

4

“Fabrication-informed Modular Design: Rapid Iterative Virtual Prototyping Approach.”

Time: 08:30 to 12:30 & 13:30 to 17:30 (full-day) | Audience: students or computational designers interested in fabrication-informed design | Participant numbers: min 10, max 15 | Requirements: laptop, with Rhino + Grasshopper version 7 installed (Packhunt platform free accounts will be supplied) | Prerequisites: none | Participation Fee: CHF 30- (coffee/tea & light lunch included)

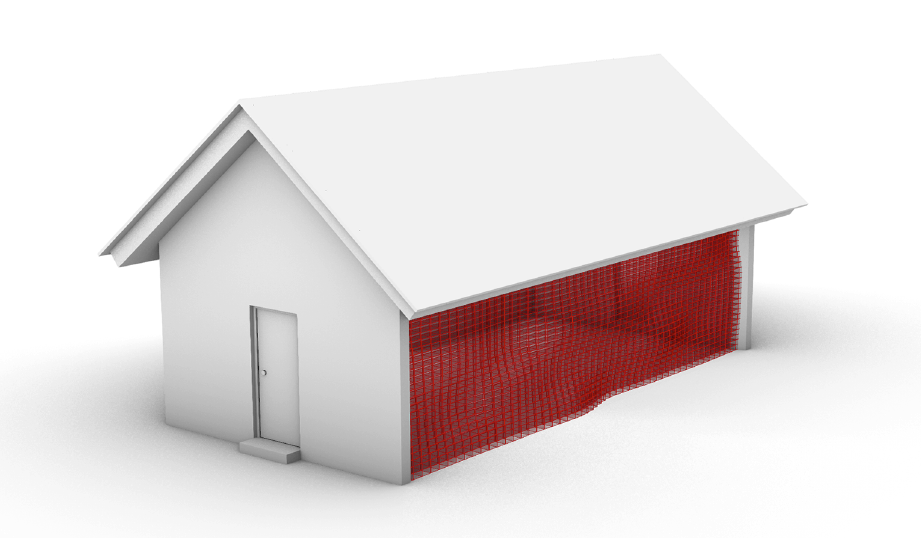

About the Workshop

In recent years, modular building approaches have seen significant growth, due to benefits such as reduced construction time, higher quality, reduced carbon, and improved circularity. During the early design phase of modular buildings, architects typically work without any feedback from competing fabricators who produce modular components such as walls, facades, and roofs. If it were possible to get direct real-time high-fidelity feedback from fabricators early in the design process, it would have the potential to significantly improve the designs that are produced. When combined with parametric modelling, this will allow for a rapid iterative virtual prototyping approach, where large numbers of design options can be explored, with each option being generated as a fully detailed 3D model.

In this hands-on workshop, you will experience how fabrication-informed modular design can be applied in practice. The workshop will be split into two parts, and in each part you will play a different role.

In the morning, you will play the role of the fabricator who is putting their building components online as web services. You will define a parametric model for a modular building component such as a wall, floor, or roof. The internal logic of the parametric model will reflect various fabrication constraints, and the output will include metadata, such as cost, performance, and circularity data. You will upload your model to the cloud, so that it becomes accessible as a web service, as part of a library of parametric modular building components.

In the afternoon, you will play the role of the architect who is interested in iteratively exploring modular design options using a data-driven decision-making approach, with high-fidelity feedback for each design option. You will create a parametric design model that is made up of embedded components from the parametric modular building components library. The parametric design model will automatically instantiate these components by calling the web-service APIs of each building component. Since all embedded components are defined by the fabricators themselves, design options will automatically acquire detailed geometry and product-specific meta-data. In general, this has the potential to support a reliable and trustworthy data-driven decision-making approach early on in the design process.

At the end of the workshop, you will present your design options to the rest of the group. We will then discuss and brainstorm the future possibilities of fabrication-informed modular design.

Tutors

Jeroen Coenders, CEO, Packhunt

Patrick Janssen, Head of Research, Packhunt

Maarten Mathot, Researcher, Packhunt

5

“Building Information Modelling with COMPAS”

Time: 08:30 to 12:30 & 13:30 to 17:30 (full-day) | Audience: students, researchers, faculty, practicing professionals | Participant numbers: min 5, max 15 | Requirements: laptop, all other required materials/software will be distributed ahead of the workshop | Prerequisites: participants should be reasonably comfortable working with Python | Participation Fee: CHF 30- (coffee/tea & light lunch included)

About the Workshop

In this workshop, participants will learn how to integrate computational structural design with BIM using COMPAS and IFC, by integrating a parametrically designed, non-standard, structural element such as a vaulted floor or an undulating bearing wall into an existing IFC file. They will use various packages from the COMPAS framework to:

- load a small building from an IFC file into a COMPAS model (compas_ifc),

- form-find a custom floor or wall (compas_fofin),

- perform finite element analysis on the custom structural element (compas_fea),

- add metadata to the custom element with a data schema for validation, and

- convert the COMPAS model, with the custom element to a valid IFC file.

Tutors

Dr. Tom Van Mele is Senior Scientist and co-director at the Block Research Group (BRG) of the Institute of Technology in Architecture at ETH Zurich, and he is the lead developer of COMPAS, the open-source computational framework for collaboration and research in architecture, structures and digital fabrication.

Li Chen is a PhD Candidate at the Block Research Group (BRG), his research focuses on the future data model for digital collaboration in AEC. He is one of the core developers of COMPAS framework and on the board of directors of COMPAS Association.

Dr. Petras Vestartas is a post-doctoral researcher within the Block Research Group (BRG). He holds BA and MA degrees in architecture from VAA (Lithuania). His PhD was completed at the Laboratory for Timber Constructions IBOIS, EPFL (Switzerland). He has developed various software applications, including compas_wood (joinery generation), NGon (polygonal mesh processing), OpenNest (2D nesting), Raccoon (CNC fabrication), and Coockroach (pointcloud processing).

6

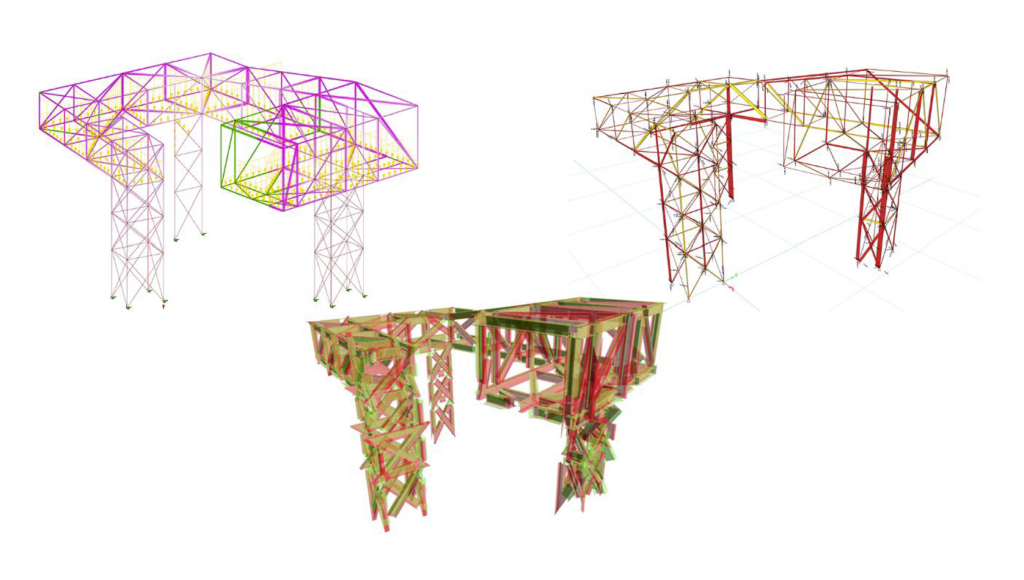

“Parametric Engineering with Karamba3D: Enhancing Collaboration and Sustainability.”

Time: 08:30 to 12:30 & 13:30 to 17:30 (full-day) | Audience: open to both students and professionals, eager to learn about new workflows LCA integration early structural design | Participant numbers: min 10, max 25 | Requirements: laptop (windows is preferred) | Prerequisites: previous knowledge in Rhino/Grasshopper/Karamba3D/Speckle/Compas would be greatly beneficial | Participation Fee: CHF 30- (coffee/tea & light lunch included)

About the Workshop

This workshop focuses on leveraging the capabilities of Karamba3D, a parametric engineering platform embedded in Grasshopper, to enhance collaborative design and incorporating life cycle analysis into early-stage structural design. We will dive into enabling effective teamwork through simultaneous work on shared sketch 3d models, facilitated by the integration of Speckle, a cloud platform designed for real-time data sharing and collaboration in the AEC industry. Participants will gain hands-on experience in utilizing Karamba3D for structural optimisation whilst leveraging the Compas framework to connect to Carbon databases to provide rapid LCA checks. The workshop aims to equip participants with the knowledge and skills necessary to foster a collaborative work environment, streamline workflows, and enhance project outcomes through the synergistic use of these advanced technological tools.

Morning: Introduction Lecture / Tutorial Session – parametric engineering with Karamba3D & collaboration in the cloud with Speckl / Exploratory work session

Afternoon: Tutorial Session – integration of LCA & visualisation of data with dashboards / Exploratory work session / Discussion

Tutors

Clemens Preisinger – Karamba3D, University of Applied Arts Vienna

Clemens is a structural engineer and researcher. Since 2010 he has been developing the parametric, interactive Finite Element program ‘Karamba3D’. He currently heads the department ‘Digital Simulation’ at the University of Applied Arts Vienna, which investigates possibilities to bring computational modelling techniques into early-stage architectural design.

Georg Lobe – Karamba3D, Technical University of Vienna

Georg has a strong digital design background and specialises in seamlessly integrating engineering with algorithmic processes into architectural design. His programming proficiency, including a deep understanding of six-axis manipulator (Kuka), reflects his expertise in software development and robotics integration.

Keerthana Udaykumar – schlaich bergermann partner (sbp)

Keerthana is a computational architect at schlaich bergermann partner (sbp) in Stuttgart. She is a part of the design team and contributes to the early design stages of bridge and stadium projects, while also developing computational tools.

Matthew Tam – Karamba3D, Bollinger+Grohmann

Matthew is a computational designer co-leading the Design Technologies department at Bollinger+Grohmann. He works at the interface of architectural, structural and computation design regularly holding workshops and is core to the Karamba3D team.

Viktória Sándor – AIT & University of Innsbruck

Viktória is an architect, working as a research engineer in the field of integrated digital urban planning at AIT while holding a senior scientist position at the University of Innsbruck. She has been involved in several research projects with the main focus on computational design, machine learning and co-design.